Products

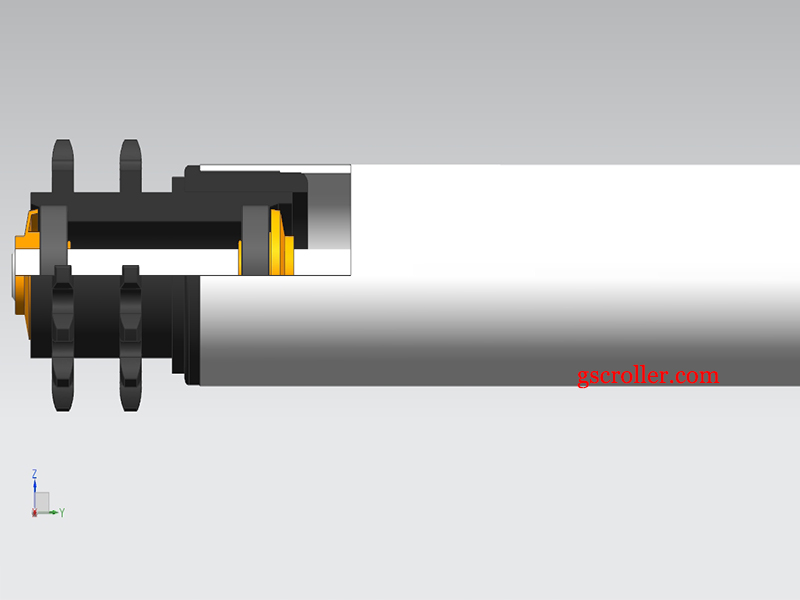

Chain conveyor roller pressed into driven roller

Conveyor roller pressed into drive roller

Gravity roller with steel sprockets in stationary-driven roller

Gravity Roller (Light Duty Roller) is widely used in all kinds of industry, like manufacturing line, assembly line, packaging line, conveyor machine and logistic strore.

|

Model |

Tube Diameter D (mm) |

Tube Thickness T (mm) |

Roller Length RL (mm) |

Shaft Diameter d (mm) |

Tube Material |

Surface |

|

PH50 |

φ 50 |

T=1.5 |

100-1000 |

φ 12,15 |

Carbon Steel Stainless Steel |

Zincorplated Chrome plated |

|

PH60 |

φ 60 |

T= 1.5,2.0 |

100-1500 |

φ 12,15 |

Note: Customisation is possible where forms are not available

Product Application

Processes

The Pressed-Into-Driven Roller

GCSroller has been a physical manufacturer and Exporter for many years, from designing the requirements to controlling the production until the product reaches the customer.

At GCS China, we understand the importance of efficient material transportation in industrial environments. To meet this challenge, we have developed a conveying system that combines gravity roller technology with the benefits of mechanical precision bearings. This innovative solution offers several key benefits to increase productivity and streamline operations.

One of the outstanding features of our conveyor systems is the use of gravity rollers. These rollers are available in tube sizes PP25/38/50/57/60 for smooth and reliable material transportation. By utilizing gravity, items can be moved effortlessly from one point to another without the need for an external power source. This not only reduces energy consumption but also ensures a cost-effective solution for material handling.

RollerShaft

Roller Tube

Roller Conveyor

Service

Our conveyor systems are designed with longevity in mind, utilizing mechanical precision bearings. These bearings are known for their exceptional strength and ability to handle heavy loads, ensuring that the rollers operate smoothly and efficiently. To further enhance durability, our rollers are galvanized, providing an additional layer of protection against corrosion and extending their lifespan. This combination of reliable mechanical bearings and corrosion-resistant rollers results in a low-maintenance solution for all your material handling requirements.

As a manufacturing facility, GCS China understands the importance of flexibility and customization. We offer a wide range of gravity rollers, allowing you to choose the most suitable option for your specific requirements. This customization extends to our conveyor systems, as we can configure them to meet your unique operational needs. Our team of experienced professionals is ready to help you find the perfect solution for your business.